Technology Services

Enhance the Wind Turbine Components and Blade Design with our state-of-the-art Engineering Technology Services. From the design idea, product developing up to operation services as well as sharing our know-how and expertise we support our clients at each project stage.

Structural Design

Calculations

By means of our state-of-the-art calculation method we assure the reliability of the structural component. Depending on the material type, the failure mode and the following standard we apply analytical, numerical and/or empirical calculation’s approach. We also perform independent calculations with the (if applicable) corresponding evaluation or verification for e.g. the test results.

Sub-Components

Sub-components are a groundbreaking method to validate complex or sophisticated local design concept that a global FE model cannot correctly determinate e.g. when the global model is based in in-plane stress approach (FE shell elements), but the local model requires a in-plane strain approach (FE solid elements). In addition, a sub-component is appropriate for large FE model in order to avoid unnecessary computing time.

Optimization

Under the structural subject the optimization comprises the improvement of the weight, material costs, shape, volume, i.a. This is specially beneficial when the standard calculations show considerably material safety margin.

Reengineering

Whether the design concept undergoes an essential change, or a design part shall be in compliance with further specifications or standards, or a component life cycle is approach, we assist or evaluate the process of design or specification modification.

Product Development

From the concept to the in-service inspections and maintenance we proactively guide you in each project stage. Each of them are essential for the success of the product, accordingly we contribute with expertise, know-how, well-coordinated effort, effective communication, adaptability to market feedback and a commitment to delivering value.

Damage Analysis

During the manufacturing, transportation, installation or in operation, a structural component can undergo failure whose cause is essential to be determinated to mitigate any potential risk. Depending on the criticality, we accomplish the corresponding investigation and coordination with the different production departments.

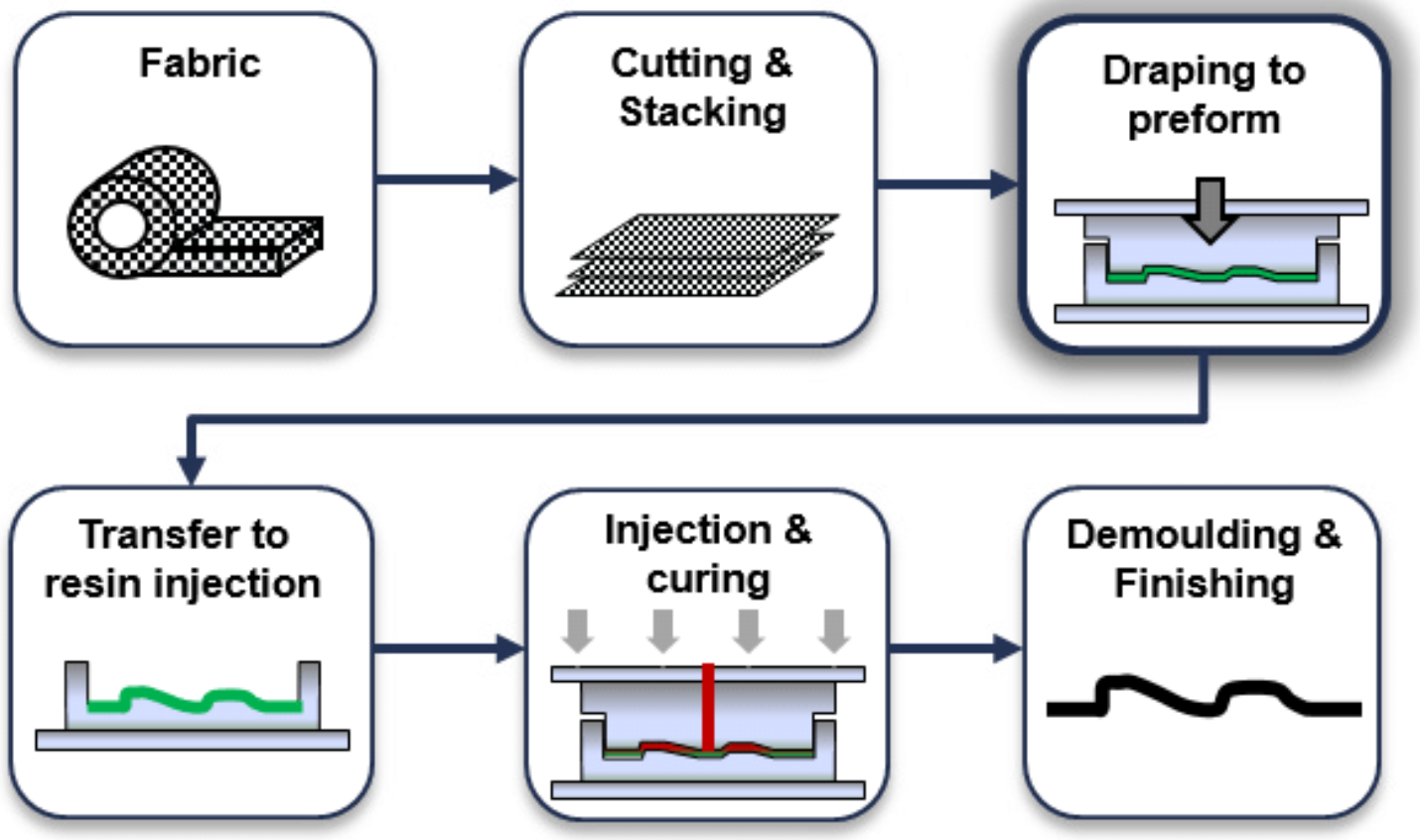

Manufacturing

Bringing the state-of-the-art manufacturing technology we deliver a product with high quality standards and an outstanding productivity. In addition, we advise for innovation, efficiency and effectiveness.

Material

Either for metallic and non-metallic material we accompany the process of composition, manufacturing, testing, mechanical properties characterization, i.a. Special consideration we pay for fiber-reinforced composites due to the extensive uncertainties that they during the manufacturing and testing for the determination of the material design values.

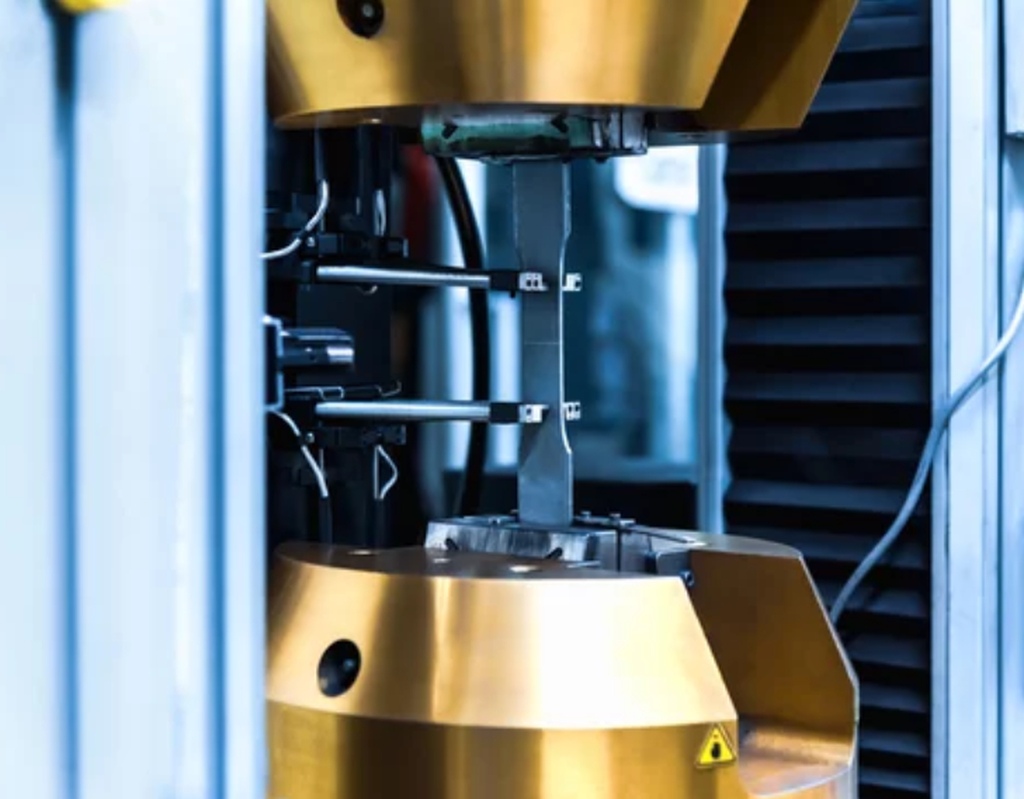

Testing

We assist you to create and perform the test representatively to the actual design. Either coupons, elements, sub-components or full scale specimen our sound expertise assure a successful test campaign and consequently to evaluate the results.

Our know-how for testing enhances comprises the FRC and Metallic materials.

We accompany the test from the specification creation, setup, execution, report creation and evaluation.

Our Prime Tests are:

a) Full-Scale Wind Turbine Blade: According to IEC-61400-23

b) Non-Metallic Materials or Elements: FRP Laminates, Sandwich Panels and adhesive joints according to DNV-ST-0376 in connection with the standards indicated in it.

c) Highly bearing-loaded Bolt: According to ISO 3800

d) Safety attachments on the wind turbine nacelle cover: Anchorage point attached or embedded to a FRP Laminate

Training

Delightedly we assist you to enhance your knowledge in:

a) Structural design: Wind Turbines Components, Fiber Reinforced Composites, Bolted Joints, Metallic Materials, Sub-Components, Optimization, Sensitivity Analysis, i.a.

b) FE analysis: Solving complex, large, recurrent issues. Performing a parametrization, sensitivity analysis, optimization, writing codes, i.a. for the FE model calculation.

c) Certification: Guidance and Interpretation of the certification specifications, standards as DNV, IEC, DIN, ISO, VDI and ASTM.

We have in-house created 300+ software for internal and customer employment using different languages as VBA, Matlab, Python and ANSYS APDL. Gladly we lease our internal software or develop new software suiting your necessities.

Our prime entirely parametrized and automatized software are:

a) BLADEsign: Creation, Elastic Properties Determination, Calculation, Failure Criteria, Evaluation, Optimization, Sub-Component of a wind turbine rotor blade.

b) FEMext: Validation and Integration of an external (customer) FE Wind Turbine Blade Model into the BLADEsign

c) WT-RB-Joint: Creation, Calculation, Failure Criteria for the Fiber Reinforced Composite (FRC) and Bolt, Evaluation of a Wind Turbine (WT) Root Blade (RB) Joint to the Hub.

d) COMPOSITE: Creation, Mechanical and Elastic Properties Determination, Calculation, Failure Criteria, Evaluation of a FRC solid or sandwich panel.

Ready to revolutionize wind energy together? Reach out and letʼs start crafting the future. Our team is eager to hear your ideas and turn challenges into triumphs. Contact us now!

Send us an Email